We decided to recover the bench cushion on the boat as one of the corners was just showing some age. As we were going to use the boat all summer we thought it would be better to cover it before it got worse. The small leather repair had been tried and was 95% successful, in that it was repaired but a perfect colour match was very hard to achieve and it showed a little.

We bought several metres of Upholstery fabric from Immanuel Fabrics at Burnley for £1 a metre. They specialise in ends of rolls or discontinued lines so you can buy really good quality fabric at tiny prices if you are not bothered that it is not this year’s colour/design.

This internet clip was a great help.

https://www.youtube.com/watch?v=C7m0No1tUHo

The first one was quite straightforward as it was almost rectangular. The issue with boat cushions and I suspect this applies to caravans etc is that the back of the cushions are thinner so that they fit snuggly under the seat back cushions. Therefore all the angles you are dealing with are odd. You are in fact covering wedge shapes. Anyway the first one went quite well so we rushed back to Burnley to buy the rest of the roll of material before someone else snapped it up.

The fabric is a short napped plush with a flame proof backing, which is kind of rubbery. I was really surprised how easy it was to sew.

The next 3 pieces were much harder shapes as they formed a ‘U’ shape around the table.

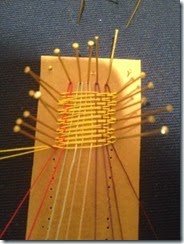

First we traced around the front edge of the cushion. The video suggests taking a pen and drawing around the cushion with the pen pointing slightly under the edge at approx 45 degree angle. This gives the sewing line and you need, and a cut line to allow approx 2cm extra for your seam allowance. The stretch fabric needs to be cut so that the finished item is slightly smaller than the cushion and so fits snuggly. We cut out the shape, leaving the back open for further adjustments.

We then placed that piece face down on the fabric and cut out the bottom of the cushion.

We then cut out a strip for the front of the cushion. We cut it to the maximum depth so that the narrower side pieces could be shaped as necessary.

We then pinned the top piece to the front piece and sewed around the edge.

**Mistake 1. We then pinned the top piece to the cushion to ensure we fit the base properly. At this point we should have turned the fabric inside out and fitted it to the cushion in reverse, as it would have been MUCH easier to get the fit right by pinning the edges, right sides together, with the wrong side showing.

**Mistake 2. We drew a line around the bottom edge and then sewed the top and bottom pieces together and then clumsily refit the whole thing and re-sewed some edges until it fit properly. Phew!! It took 5 refits which means we had to wrestle the cushion in and out of the fabric 4 times, phew again!

We ended up with two flaps at the back of the seat. We trimmed and neatened the top and bottom flaps so that they fit nicely with an overlap.

Next, I sewed the velcro along the edges, sewing all the way around the velcro edges to make sure it was secure.

We chose to use Velcro instead of a zip. 1. Because we thought it would be easier and 2. Because as the seats sag a little with wear the velcro can be un-fastened and re-fastened to tighten the fit, and another strip could be added if necessary, as it is underneath the seat and so will not show.

The finished seating in place.

Note the dual purpose collapsible fruit bowl/colander. Beautiful and Useful.